ABOUT OUR COMPANY

ABOUT OUR COMPANY

Brise Chemical

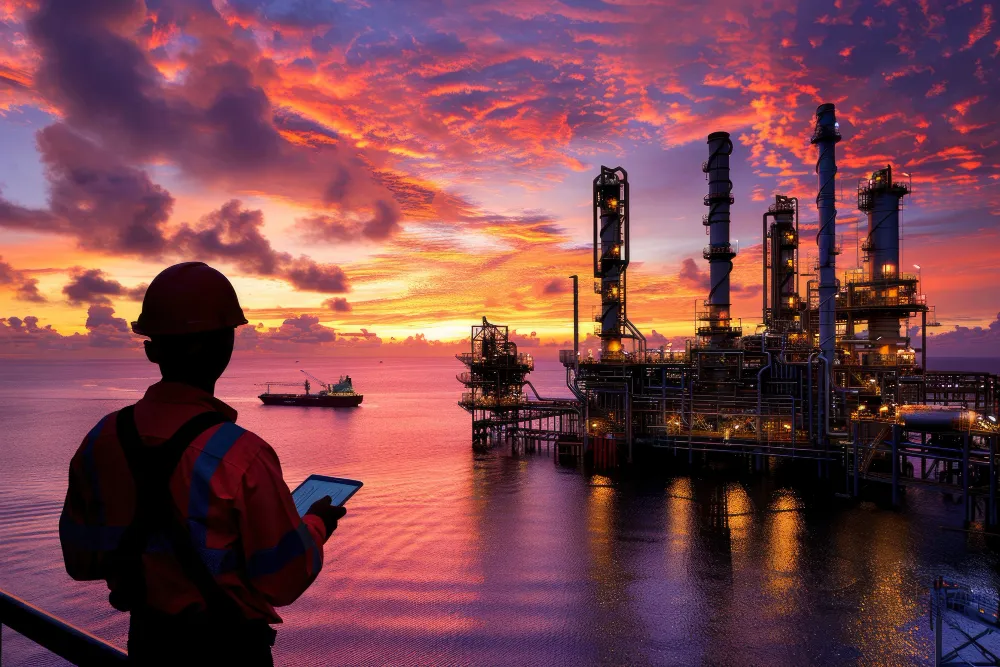

The company is founded by professionals having rich experience in the field of turbo-machineries manufacturing, Oil & Gas, Refineries, Industrial Gas Plant and have thorough knowledge of Engineering-Procurement Construction and Project-Management-Consultancy domains.

The company is involved in design, engineering, manufacturing and installation of various chemical and gas plants. Our focus is also on researching and developing innovation chemical and gas technologies for the betterment of human life.

Innovating the Future of Industrial Gases

Innovating the Future of Industrial Gases

Our Products & Technologies

Industrial Oxygen

Our Industrial Oxygen Generator Plants are designed to deliver consistent, high-purity oxygen directly at the point of use—helping industries improve

Medical Oxygen

Reliable PSA/VSA technology providing a continuous on-demand supply of 93%-96% purity oxygen while reducing costs by up to 80%.

Balance Of Plant

At Brise Chemicals Pvt. Ltd., our Balance of Plant (BoP) solutions form the backbone of reliable, safe, and efficient industrial

Air Separation Unit

Large-scale cryogenic plants engineered for the high-volume production of liquid oxygen, nitrogen, and argon with low specific power consumption.

Purification Plant (CH4, CO2)

Dual-plant adsorption technology for methane enrichment of biogas and high-value carbon dioxide recovery for commercial use.

UHP GAS Purification Plant (N2, O2, H2, Ar)

Specialized deoxidation and three-bed TSA dryer systems delivering ultra-dry, contaminant-free gas with dew points as low as -70 degree.

Nitrogen Generation Plant

Compact, fully automatic PSA systems utilizing Carbon Molecular Sieves to deliver on-site nitrogen at 99.999% purity.

Oxygen Generation Plant

Reliable PSA/VSA technology providing a continuous on-demand supply of 93%-96% purity oxygen while reducing costs by up to 80%.

Green Methanol Production Plant

An advanced catalytic synthesis process that recycles captured CO2 and renewable H2 into high-grade fuel.

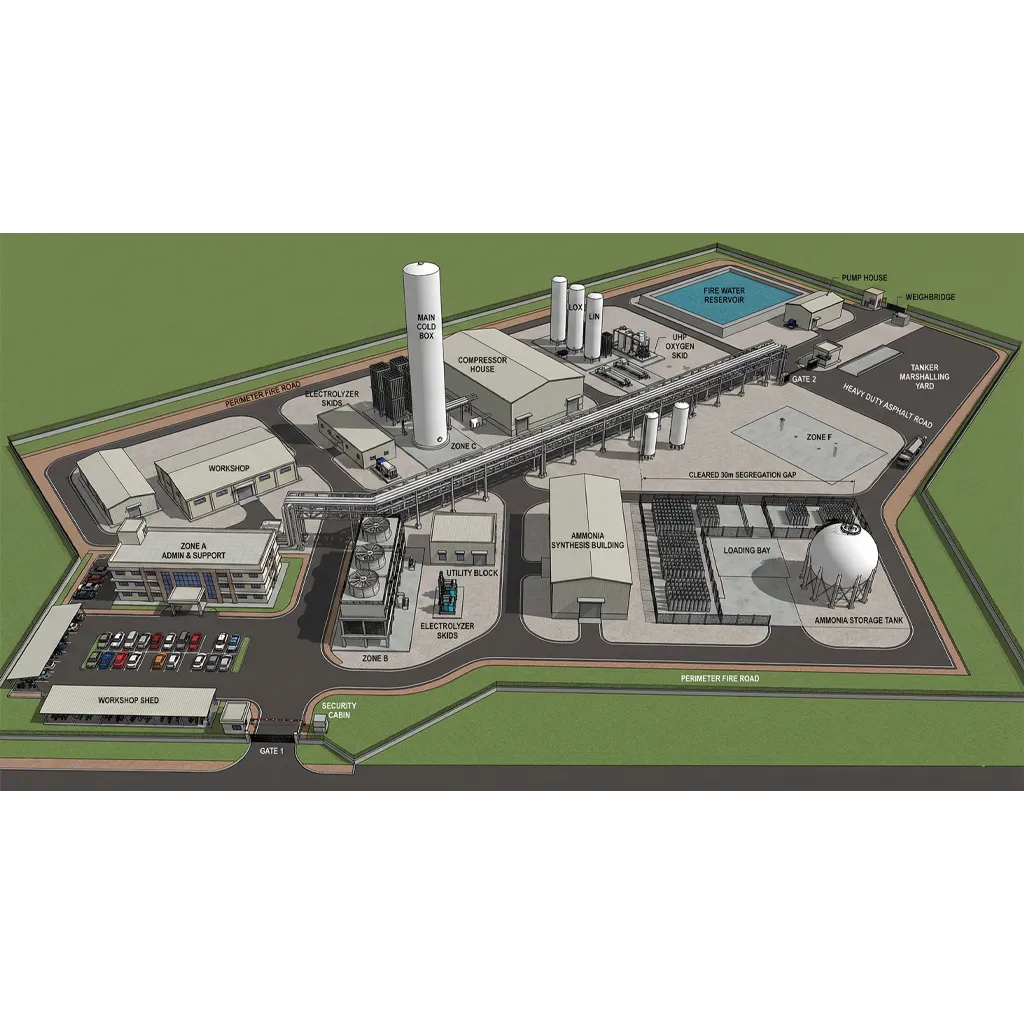

Green Ammonia Plant

Integrated Haber-Bosch reactor systems capable of producing up to 200 TPD of green ammonia with 99.99% purity.

Alkaline Electrolyser

High-efficiency bipolar alkaline designs featuring proprietary electrode coatings to reduce power usage and simplify manufacturing.

Hydrogen Generation Plant

Advanced electrochemical systems that convert de-ionized water into high-purity hydrogen for diverse industrial applications.

Successful Project

AMC / CMC Contracts

Operational Performance

Patented Technologies

We are Brise Chemicals

ABOUT

Transforming With Innovations

Connecting all the industries and making a bridge among all in this revolutionary era of industrialization and development with our years of knowledge.

Innovation, Service, Certification, Production, and Development are the most exclusive words nowadays, and combining all of them with the years of knowledge in serving and building, we Brise Chemicals stands. The only Vision is to make the most advanced gas and chemical technologies available at affordable value for the well-being of human lives. We at Brise focus on solving problems through technology innovations so that our products can be put to use for the betterment of society at large. We understand that we are in to technology business and how important it is to innovate consistently and make it a habit

Designing Life-Enhancing Technologies

Designing Life-Enhancing Technologies

Our Services

Basic Enginering Package

Providing the essential technical blueprint, including detailed P&IDs and equipment sizing, for seamless plant construction.

Enginering Services

Delivering end-to-end technical expertise in process design, automation, and fabrication for complex gas and chemical plants.

FEED Study

Establishing a precise technical and financial roadmap through detailed process simulation and risk assessment before project execution.

AMC / CMC

Ensuring maximum plant uptime and lifecycle reliability through expert preventive maintenance and comprehensive spare parts management.

Precision Engineering for the World's Most Demanding Sectors

Precision Engineering for the World's Most Demanding Sectors

Industrial Sectors We Serve

Healthcare & Medical

Delivering high-purity medical oxygen and vacuum systems to ensure the highest standards of patient care and safety.

Oil & Gas

Providing expert EPC solutions and gas purification for mission-critical refinery operations and petrochemical processing.

Steel & Metal Processing

Enhancing furnace efficiency and metal quality with specialized industrial gas generation and thermal treatment solutions.

Chemical & Petrochemical

Designing and installing advanced process plants for complex chemical synthesis and safe gas management.

Energy & Power Generation

Leading the transition to clean energy through innovative hydrogen generation and alkaline electrolysis technologies.

Food & Beverage

Supporting preservation and packaging integrity with high-purity nitrogen and inerting gas solutions.

Electronics & Semiconductor

Ensuring ultra-high purity gas environments essential for the precision manufacturing of advanced electronic components.

Automotive & Manufacturing

Optimizing production with custom turbo-machinery and specialized gas systems for large-scale industrial estates.

Brise In-house Capabilities

Project Management

Brise ensures smooth and reliable project delivery through expert LSTK management. Our team drives every phase—from planning to handover—with precise scheduling, cost control and proactive risk management.

Advanced Programming & Control Systems

Our PLC, SCADA and DCS-based control systems , enabling precise automation of industrial gas plants. Our expertise ensures optimized process control, safety interlocks and realtime monitoring for stable and efficient operations.

In-House Catalyst Coating Facility

Brise operates a specialized High Velocity Oxy-Fuel (HVOF) coating facility designed to meet the demanding requirements of hydrogen production and gas processing applications.

Process Engineering

Brise has strong expertise in industrial gas technologies including ASU, Hydrogen, Syngas, CO₂ capture and LNG. Our team develops detailed PFDs and P&IDs, performs heat and material balances and carries out precise equipment sizing and specification.

Fabrication

Brise has fully integrated fabrication capabilities for industrial gas and hydrogen projects, supported by advanced workshops and strict quality systems. Our fabrication processes follow global standards with certified welding procedures, NDT inspection and rigorous QA/QC to ensure reliability, safety and long service life of all fabricated equipment.

FAQ

FAQ

Freequently Asked

Questions

Find answers to your most frequent questions about our gas technologies, engineering services, and industrial solutions.

-

What core expertise does Brise Chemical bring to the industry?

What core expertise does Brise Chemical bring to the industry?

Brise Chemical is founded by professionals with deep experience in turbo-machinery, Oil & Gas, refineries, and industrial gas plants.

-

What gas generation solutions do you offer?

What gas generation solutions do you offer?

We provide comprehensive systems for Oxygen (Medical and Industrial), Nitrogen, and Hydrogen generation.

-

What is a FEED Study, and do you provide it?

What is a FEED Study, and do you provide it?

A Front-End Engineering Design (FEED) study focuses on technical requirements and rough investment costs; it is one of our core service offerings.

-

How does Brise Chemical contribute to environmental safety?

How does Brise Chemical contribute to environmental safety?

We focus on "Be Safe Controls Environment" by developing innovative technologies for the betterment of human life.

-

Are you involved in the future of energy?

Are you involved in the future of energy?

Yes, we are actively involved in Hydrogen Liquefication and Ammonia Synthesis to support the global transition to clean energy.

WORKING PROCESS

WORKING PROCESS

Engineering a Sustainable Industrial Future

At Brise Chemical, we utilize a structured EPC (Engineering, Procurement, and Construction) approach to ensure every project is efficient, safe, and environmentally responsible. Our process transforms complex challenges into sustainable industrial assets through three core phases:

Phase 1: Strategic Engineering

- We develop Basic Engineering Packages and FEED Studies to ensure project feasibility.

- Our designs prioritize safety and environmental control for chemical and gas plants.

- We focus on creating reliable, efficient blueprints that meet global industrial standards.

Phase 2: Innovation & Technology

- We specialize in Alkaline Electrolysis and Hydrogen Generation Plants for clean energy.

- Our expertise includes Hydrogen Liquefication to support the future of green fuel.

- We manufacture high-performance gas generation systems using sustainable practices.

Phase 3: Execution & Maintenance

- We manage the full installation and commissioning of advanced gas purification systems.

- Our technologies ensure clean outputs and the betterment of human life through gas purity.

- We provide AMC/CMC services to maintain long-term operational efficiency and safety..

CLIENT’S REVIEWS

CLIENT’S REVIEWS

Clients Best Feedback About

Brise Chemical